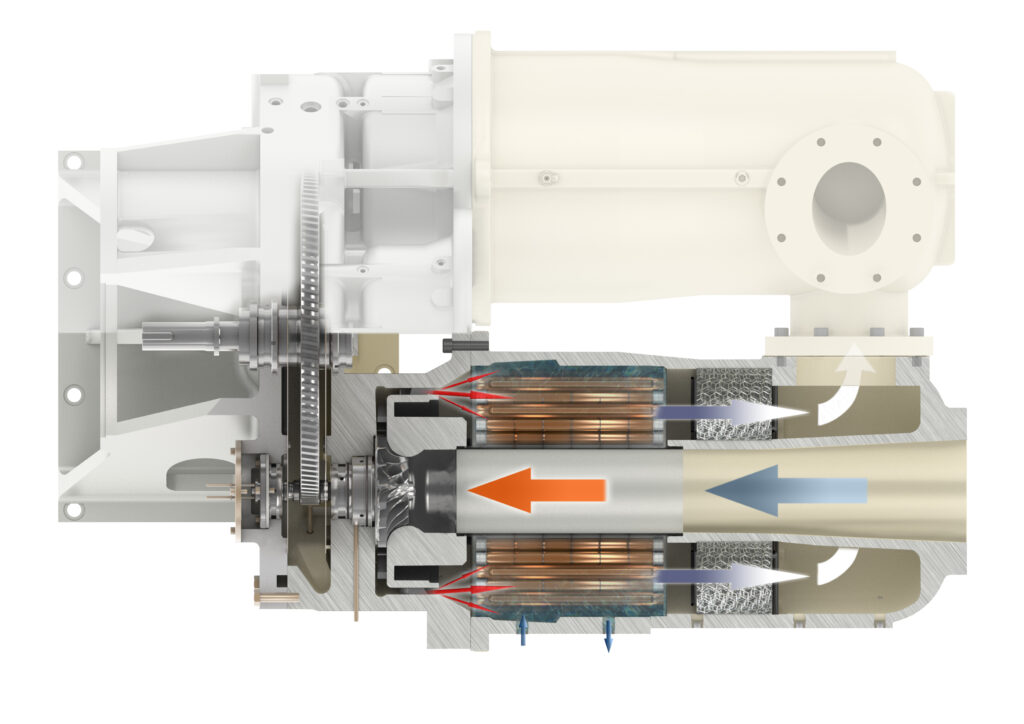

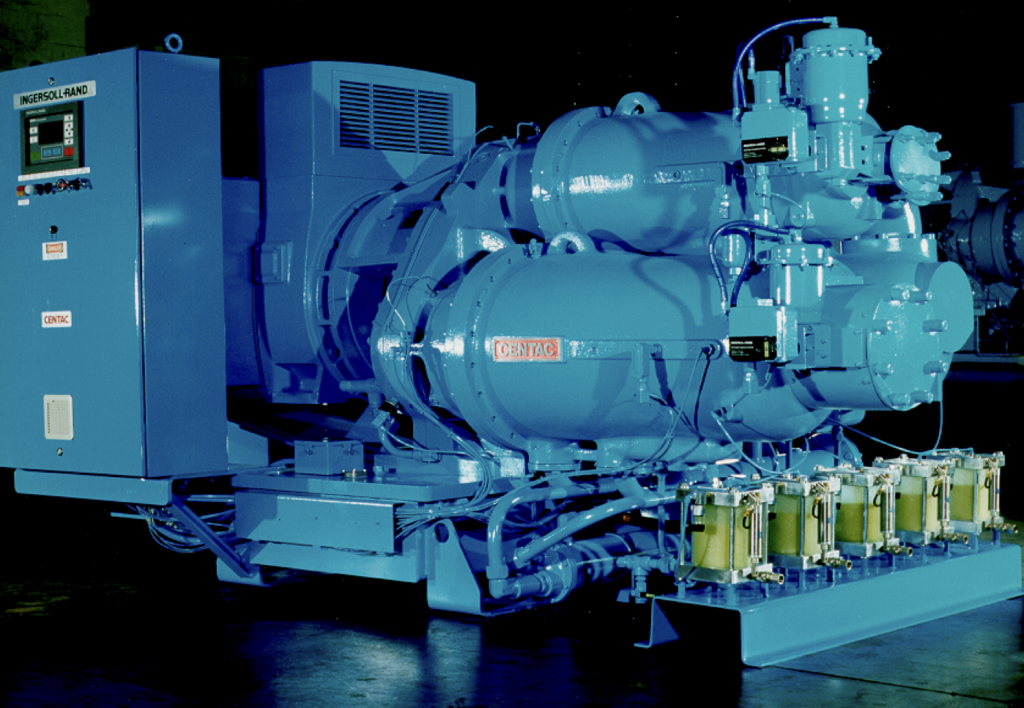

Integrally geared centrifugal air compressors are a cornerstone of industrial and manufacturing operations. They are the preferred technology for plant and instrument air systems due to their high flow rates, superior energy efficiency, and robust design. Built for continuous duty, these compressors can operate for years before requiring major inspection or service.

One defining feature of centrifugal air compressors is their multi-stage design. Each stage compresses air and then uses interstage coolers to remove the heat generated during compression. These coolers also condense and remove much of the entrained water vapor via stage condensate drains. This process is critical—because if cooling performance degrades, both efficiency and reliability can suffer dramatically.

The Threat of Foreign Matter Build-Up (FMB)

A primary challenge to maintaining cooler performance is Foreign Matter Build-up (FMB), which is common in industrial environments. Poor-quality inlet air is the usual culprit. Over time, particles and contaminants settle onto internal surfaces, including the aerodynamic components, water passages, and condensate drains.

This accumulation restricts airflow and coolant circulation, significantly reducing the heat transfer capability of the cooler. If left unaddressed, it can cause pressure drops, overheating, and ultimately lead to equipment failure. In the worst cases, FMB may result in the compressor nearing surge conditions—a dangerous operating state that requires immediate shutdown and remediation.

Airside and Waterside Fouling: What to Watch Out For

While airside restrictions can impair performance, the most serious impact of FMB lies in its effect on heat transfer efficiency. As deposits form on the cooler’s internal surfaces, they act as an insulating barrier, preventing effective heat dissipation from the compressed air.

High discharge air temperatures—sometimes exceeding 350°F—compound the problem. If the air isn’t cooled sufficiently before entering the next stage, it disrupts the pressure-flow relationship and increases the risk of surge. This situation can render the compressor inoperable and eliminate its ability to supply compressed air.

Chemical Ingestion and Corrosive Damage to Integrally Geared Centrifugal Air Compressors

FMB isn’t limited to particulate buildup. Chemical ingestion is another serious concern. When moisture-laden compressed air contains certain gases, acids can form that corrode metal components and seals. This acid attack can degrade cooler fins, making them brittle and prone to flaking.

These flakes may pass through the compressor and damage downstream components. While some particles are caught in the moisture separator, it is not a guaranteed safeguard. If the separator clogs, it adds another layer of restriction and mimics the effects of cooler fouling—without the associated heat transfer issues.

Five Key Indicators of Cooler Health

To maintain optimal performance, it’s vital to monitor the condition of interstage coolers using five key indicators:

- Cold Temperature Difference (CTD) – Calculated as discharge air temperature minus cooler inlet water temperature. A CTD above 22°F usually signals fouling.

- Cooling Water Temperature Rise – Indicates how much heat is being absorbed by the coolant.

- Differential Air Pressure – Increased pressure drop suggests flow restriction or blockage.

- Cooling Water Pressure Drop – Helps detect buildup or fouling in water passages.

- pH Value of Condensate – Acidic (<6) or basic (>8) readings point to chemical ingestion or internal leaks.

By tracking these values over time, maintenance teams can catch early signs of cooler degradation and take corrective action before serious issues arise.

Diagnosing FMB Without Historical Data

Even if a facility lacks trending data, a simple CTD check can reveal fouling. Most OEMs provide model-specific performance targets, and a CTD greater than 22°F is usually a red flag. In older compressors, you can still obtain differential air pressure readings from control panels or manually via pressure gauges installed on interstage piping.

When testing for chemical damage, use litmus paper on the condensate. A pH below 6 indicates corrosive acids; a pH above 8 could mean coolant has breached into the airstream—a condition that accelerates fouling and may cause mechanical wear.

Preventative Maintenance for Integrally Geared Centrifugal Air Compressors: The Best Defense

Preventative maintenance remains the most effective strategy to avoid unplanned downtime. Cooler health directly influences a compressor’s efficiency and reliability. Ignoring FMB or chemical degradation can trigger cascading system failures, costly repairs, and production losses.

Proactively monitoring CTD, pressure differentials, and condensate pH, combined with regular inspections and cleaning, helps facilities stay ahead of problems. Compressor OEMs often supply detailed maintenance guidelines, and following these can significantly extend equipment life.

Protect Your Integrally Geared Centrifugal Air Compressors with Proactive Cooling System Care

The health of your centrifugal air compressor hinges on the performance of its interstage coolers. Contaminants, chemical exposure, and fouling can silently erode efficiency and put your operations at risk. By recognizing the signs of degradation early and implementing a structured monitoring routine, maintenance teams can ensure compressors run reliably and at peak performance.

Don’t wait for signs of failure—take action now to inspect, trend, and maintain your cooling systems. The return on proactive care is clear: lower energy costs, fewer shutdowns, and longer equipment life.