Air compressors are essential in industrial, automotive, and construction settings, but selecting the right one depends on your specific application. This article reviews the main air compressor types, including rotary screw, reciprocating (piston), centrifugal, and scroll compressors. We’ll also compare their features, performance characteristics, and best-use scenarios to help choose the right compressor for your operational needs.

Understanding Air Compressors

Air compressors are mechanical devices that utilize electrical, fuel, or kinetic energy to pressurize air. This air is then stored in a tank or delivered directly to pneumatic tools and machinery to carry out work. Because pressurized air is a reliable energy source, air compressors are prevalent across diverse industries. Examples of applications include powering jackhammers and paint sprayers, as well as controlling valves and actuators in automation systems.

Engineers evaluating air compressors must understand several fundamental parameters:

- PSI (Pounds per Square Inch): The pressure rating that indicates the force of the compressed air.

- CFM (Cubic Feet per Minute): The volumetric flow rate of air delivered by the compressor, typically under specified pressure conditions.

- Duty Cycle: Expressed as a percentage, this refers to how long the compressor can run without cooling off. A 100% duty cycle is ideal for continuous-use applications.

- Oil-Free vs. Oil-Lubricated: Oil-lubricated compressors offer durability and cooling but require maintenance and filtration. In contrast, oil-free models are desirable where air purity is critical.

Compressors fall into two main categories: positive displacement (e.g., piston and screw types) and dynamic (e.g., centrifugal). These air compressor types each have specific benefits depending on flow, pressure, and duty demands.

- Positive Displacement Compressors: Mechanically reduce air volume to increase pressure (e.g., rotary screw, piston, scroll).

- Dynamic Compressors: Rely on kinetic energy and velocity conversion using impellers to generate pressure (e.g., centrifugal).

Overview of Main Air Compressor Types

Air compressors vary significantly in terms of compression mechanics, energy consumption, air purity, footprint, and service needs. Here are the most common air compressor types.

Rotary Screw Compressors

Generally, rotary screw compressors operate using two intermeshing helical rotors that continuously compress air as it moves through the chamber. This design offers high volumetric efficiency as well as continuous-duty operations in industrial environments.

- Oil-Injected Rotary Screws: Robust, cost-effective, and suitable for general-purpose use across industrial sectors, but require downstream oil separation.

- Oil-Free Rotary Screws: Ideal for applications demanding contamination-free air, such as food processing, electronics, and pharmaceutical manufacturing.

Advantages:

- Continuous flow (100% duty cycle).

- Lower operating temperature in comparison to reciprocating units.

- Minimal pulsation and low vibration.

- Integrated designs with variable speed drive (VSD) options for energy optimization.

Best Applications:

- CNC machining.

- Packaging lines.

- Food and beverage bottling plants.

- Large-scale automation systems.

Reciprocating (Piston) Compressors

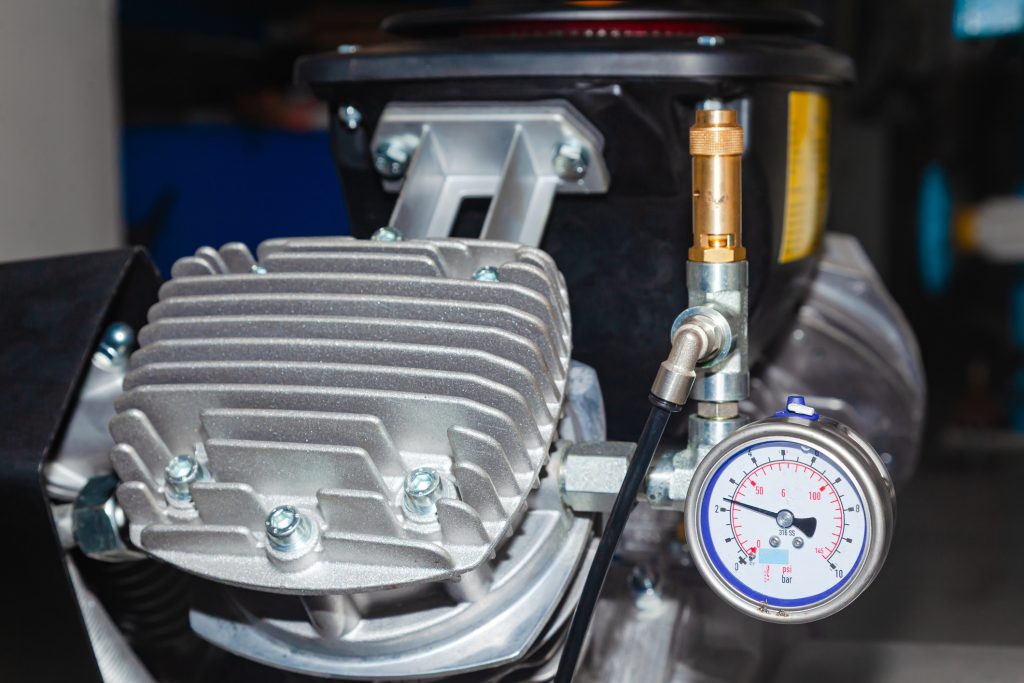

Reciprocating compressors use a piston-cylinder assembly to compress air in discrete cycles. The air is drawn into a chamber, compressed via piston movement, and discharged into a receiver tank.

- Single-Stage Models: Provide up to ~125 PSI, suitable for low-pressure applications.

- Multi-Stage Models: Compresses air in two or more steps to reach ~175 PSI. Hence, offering higher efficiency and air delivery for moderate to heavy-duty applications.

Advantages:

- Simple mechanical design.

- Lower upfront cost.

- Easy to maintain and repair.

Best Applications:

- Automotive garages.

- Carpentry and woodworking shops.

- Light industrial maintenance.

Centrifugal Compressors

Centrifugal compressors (a type of dynamic compressor) utilize high-speed impellers to accelerate air radially and then convert that velocity into pressure through a diffuser. They are inherently oil-free and are designed for high-volume, continuous operations.

Advantages:

- Very high flow rates (thousands of CFM).

- Low maintenance (no contact parts in compression stage).

- Efficient in multi-stage configurations.

- Ideal for ISO Class 0 air purity standards.

Best Applications:

- Refineries and petrochemical complexes.

- Power plants.

- Large refrigeration and air separation units.

- High-capacity air-driven systems.

Scroll Compressors

Scroll compressors operate using two spiral scroll elements: one stationary, while the other orbits. Because the orbiting scroll compresses air toward the center, the design ensures smooth, pulsation-free flow with minimal noise.

Advantages:

- Compact and lightweight.

- Extremely quiet and low vibration.

- Fewer moving parts, thus reducing maintenance costs.

- Energy-efficient in low to medium flow applications.

Best Applications:

- Electronics assembly lines

- Medical and dental facilities

- HVAC and laboratory systems

- Food packaging and bottling

Comparing Features of Air Compressor Types

The following comparison outlines the key differentiators between the four main compressor types to assist with performance-based decision-making:

| Feature | Rotary Screw | Reciprocating (Piston) | Centrifugal | Scroll |

| Energy Efficiency | High | Moderate | Very High | High |

| Noise Level | Low | High | Moderate | Very Low |

| Maintenance Needs | Low | Moderate to High | Low | Very Low |

| Initial Cost | Medium to High | Low | Very High | Moderate |

| Footprint | Medium to Large | Variable | Very Large | Compact |

| Duty Cycle | 100% (Continuous) | ~50–75% | 100% | ~100% |

| Air Purity Options | Oil-Free Available | Mostly Oil-Lubricated | Inherently Oil-Free | Inherently Oil-Free |

| Best Use Case | General Industry | Light Industry/DIY | Large-Scale Utilities | Sensitive Environments |

Selecting the Right Air Compressor Types for Your Application

The process of selecting the right air compressor should account for process demands, environment, maintenance resources, as well as energy cost. Proper selection directly impacts lifecycle costs, equipment uptime, and system reliability.

Here are the best-fit guidelines:

- High-duty cycle, continuous demand: Rotary screw compressors are optimal due to their continuous operation capability, reliability, and integrated controls. They handle varying loads well, especially with variable speed options.

- Cost-sensitive, intermittent usage: Piston compressors are a good fit for budget-conscious operations with low daily runtimes. Also, their simple construction allows for in-house maintenance.

- High-capacity, low-maintenance operations: Centrifugal compressors deliver massive volumes with minimal mechanical wear, hence ideal for refineries, chillers, and process air.

- Space-restricted, low-noise applications: Scroll compressors shine in medical labs, cleanrooms, and HVAC systems due to their compact, oil-free, and quiet operation.

Additional factors to evaluate:

- Required pressure range and flow profile.

- Ambient environmental conditions (temperature, humidity, contaminants).

- Energy efficiency goals (e.g., ISO 50001 compliance).

- Total Cost of Ownership (TCO): Initial investment + maintenance + energy consumption.

High-Quality Air Compressor Types with Dynamic Rentals

Dynamic Rental Solutions offers a comprehensive range of high-performance air compressors designed to meet the diverse needs of various industries. Moreover, our rental fleet includes positive-displacement compressors, centrifugal compressors, axial compressors, and high-pressure centrifugal and reciprocating compressors (up to 900 CFM). These options cater to various applications, from manufacturing and construction to power generation and petrochemical industries. Benefits include flexible rental terms, expert technical support, and rapid delivery.

For more details, visit the Dynamic Rentals Product Page.